Rapidly increasing demand for energy-efficient mass transit solutions is driving increased adoption of hybrid and fully electric power. Transit system designers have increasing needs for longer life and higher durability on components, particularly the actuators that enable safe, flexible connections to power sources”. Fortunately, a new line of electric linear actuators is now available on the market to meet this need.

The role of actuators in electrified vehicles

Actuators enable electric trams, buses and trains to connect and disconnect with power sources intermittently. This is not as necessary in most conventional applications because they rely on a single power source to which they connect once in the morning and stay connected until the end of their day. Hybrid vehicles, on the other hand, use battery power for routes that extend beyond city limits but switch back to cleaner and more economical overhead power many times as they run their routes. This will become increasingly important as the number of riders increases.

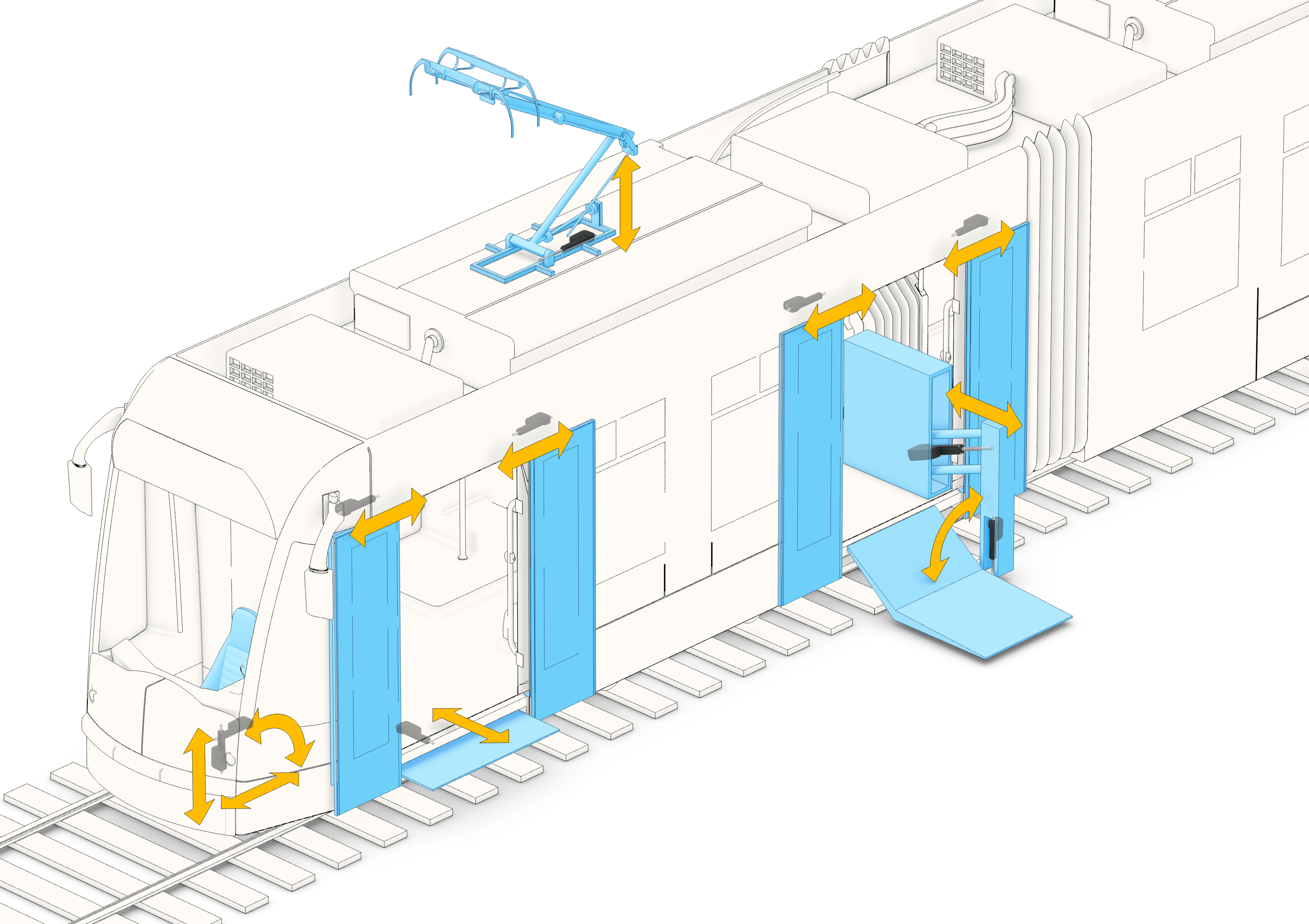

Actuators manage the overhead switching by controlling spring-loaded pantographs — mechanical assemblies that sit on top of a vehicle and elevate above to connect with overhead power lines. (Figure 1) A spring raises the pantograph to connect and maintain contact with the overhead power line, and the actuator pulls the pantograph away from the power source when switching to battery power. In other designs, the actuator may pre-load the spring that raises the pantograph to the overhead power line. More efficient intermittent switching reduces the need to add aesthetically challenging and potentially dangerous overhead wiring within city limits as mass transit use increases.

Figure 1: Actuators enable the control of hybrid trains, which temporarily connect to overhead lines (image courtesy of Thomson Industries, Inc.)

Some designs use pneumatic actuators to manage pantograph connectivity, but the related air compression gives off moisture that can cause clogging and, in low temperatures, icing. Pneumatic solutions also need many more components, including pumps, pipes and compressed air systems. The increase in ridership compounds such issues, making pneumatic solutions increasingly less attractive as traffic increases.

Actuators also guide the switching to recharging stations, helping hybrid buses get the power they need to operate during the day. And for trains that get power from third rails, actuators control the extension of the contacts from the train to the powered rail.

Where existing applications might be demanding actuators with lifetimes between 20,000 and 30,000 cycles, daily cycle increases resulting from increased ridership are expected to require actuators with lifetimes in the 500,000 – 1,000,000 cycle range.

Extending actuator life

Creating a longer-life actuator requires evaluation of at least four areas: ball screw selection, motor design, braking and environmental resistance.

Actuators in mass transit applications translate rotational motion into linear motion through a ball screw. Selecting a ball screw that can handle up to a million cycles in its lifetime requires advanced optimization calculations that balance load and speed by upgrading the nut and screw assembly. These calculations can get quite complex but essentially involve increasing the load capabilities of the screw and nut assembly by using a larger diameter ball screw and a nut with twice the number of balls that form the connection between nut and screw. This construction greatly increases the life of the ball screw and nut.

Motor design also impacts actuator life. Most actuators currently used on electrified vehicles use traditional contact brush-based DC motors. But the brushes eventually wear out ? much too soon for the extended use that the transit designers are projecting. A better alternative is to replace the brushes with an electromagnetic field, which removes the contact brushers entirely and can last virtually forever. There will, of course, be some wear on bearings or other parts of the motor, but the longevity then does not depend on brush life.

The long-life, robust Electrak® HD actuator from Thomson is designed to handle up to one million cycles at its rated max load.

A brushless DC motor also requires a slightly different user interface and will help control braking in pantograph operation.

In a pantograph, the actuator is working against a spring. In one direction, it is the opposing force; in the other direction, it is an assisting force. An opposing spring provides stable, more controlled speed in one direction. An assisting spring, on the other hand, allows a more free-wheeling operation that must be controlled. Typically, the speed is controlled with a friction brake when the spring is assisting. In the case of extended use, the friction brake will wear down and limit the life of the actuator.

Along with an upgraded motor, this new actuator solution features an upgraded ball screw design, an electromagnetic load holding brake and an integrated electric motor control. This better approach uses the brushless motor to control the speed and an electromechanical brake to hold the load in place once the actuator stops. Actuators used in public transit applications are already subject to health and safety regulations, but expanded use will bring greater improvements there as well. Where vehicles in less-frequent operation might be able to use a lower ingress protection level such as IP65 on current solutions, expanded operation of a train moving at 100 kilometers an hour would result in greater exposure to environmental forces and would likely require a higher protection level. Likewise, operation in seaside communities would have greater exposure to corrosion in salt air, likely IP66 or even IP69K. These factors, combined with stringent public safety standards preventing use of toxic materials, are driving actuator suppliers to make certain that the materials and sealing strategies they use will provide safe performance for the 20 or 30 years that the vehicles themselves may last.

What’s coming down the road?

In today’s transportation applications, actuators primarily provide the switching function, something they will continue to do. But switching requires some onboard electronics, which enables actuators to communicate with each other and with other devices, providing operators with information such as feedback on the position of the pantograph and creating the need for actuators to evolve.

Although actuators used for charging stations are among the first components that must be upgraded to accommodate extended ridership and expanded electrification, other suitable actuator applications may soon follow, including door operation, step levelling, rail car connecting, and gap control for safe and easy passenger access. Until today these applications have primarily been managed by pneumatic or hydraulic actuators, but with increased cycles and the requirement for more efficient and robust components, engineers should consider the more aptly suited electromechanical actuators for their designs.