Fundamental ball screw technology hasn’t changed much since 1929 when Rudolph G. Boehm patented what he called an “anti-friction” nut. The ability to move heavy loads smoothly and precisely is a key process which continues to enable engineering innovation today. Nowhere is this more evident than in the production of fiber optic filaments, where ball screws are helping manufacturers meet the growing demand for fiber optic cables generated by 5G communications.

Delivering Fiber Optic Strands for 5G Communications

Wireless carriers are just beginning to roll out 5G communications, but expectations with even the most conservative estimates are projecting at least a 10-fold speed increase over 4G. This will impact everything from cell phones and laptops to driverless cars. The realization of 5G communications is boosting the demand for high-bandwidth fiber optic cable, which requires continuous improvement in the fiber optic manufacturing process. This begins with the creation of highly treated, multilayered silicon rods called preforms. These provide the silicon that will eventually be drawn into filaments approximately the width of a human hair and joined with hundreds of similar strands to produce the fiber optic transmission cables that will carry the 5G signals.

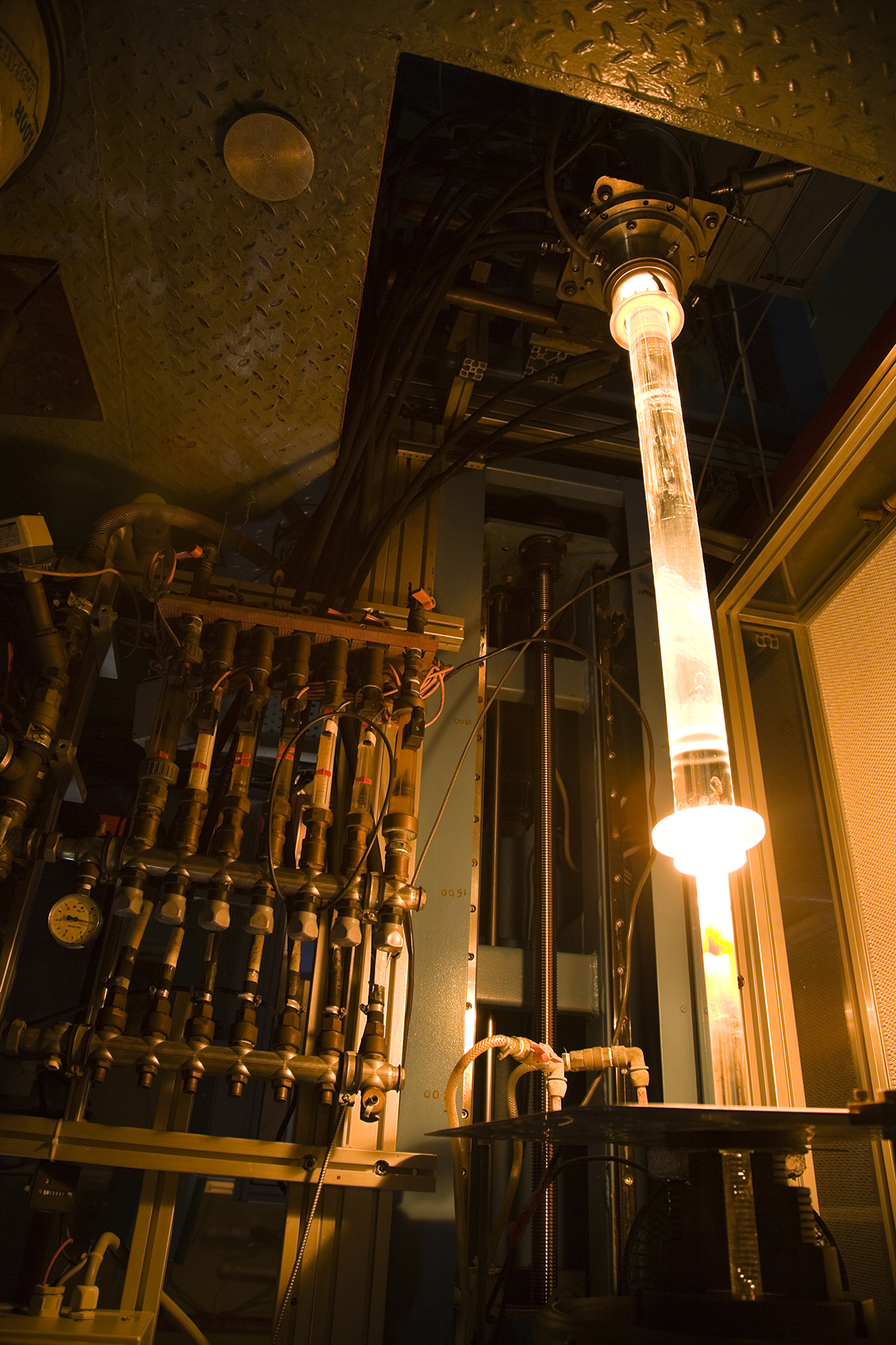

To start the conversion of the preform into a single strand, a technician climbs to the top of a drawing tower and loads it into a feed mechanism that will lower it into a high-temperature furnace. Once the preform arrives at the heating element, gravity takes over, and the molten silicon drips and narrows to its intended diameter. As it cools and hardens, the filament passes through a laser micrometer to assure 99 percent width consistency. It is then pulled onto a take-up spool that will gather as much as 10 kilometers of filament before transfer to a fabricator for incorporation into the final cable.

Figure 1 Final stages of production, in which silicon filament narrows to its desired width, cools and passes through a laser micrometer before being pulled onto a take-up spool

Critical to the success of the process is the control over the speed with which the system feeds the preform. Due to the thin nature of the fiber, slow and steady movement of the feed unit (one meter per hour) ensures that the production is stable. Any faster than that, and the furnace will be unable to melt the preform fast enough. Anything slower will break the continuity of the stream. Many of the world’s leading fiber optic wire producers accomplish this with ball screw technology, which provides high stability and smooth movement at such low speeds.

Selecting Ball Screws for Fiber Optic Drawing Towers

In a typical ball screw configuration, the feed mechanism anchors to the ball screw nut with a rod. The nut rides down the vertically oriented ball screw, carrying the preform feed mechanism with it toward the heating unit. Requisite travel distance from the top of the drawing tower to the furnace is 6-8 meters, which requires a long screw.

Figure 2: Thomson ball screws drive delivery of silicon preforms to heating elements for melting, dripping and eventually hardening into a fine filament that is then pulled onto a take-up spool.

To optimize production of fiber optic cable, three important factors must be taken into account:

- Pitch diameter. Speed control and efficiency are impacted by pitch. Standard dimensions such as 50 x 10 mm, 63 x 10 mm and 80 x 10 mm are ideal to ensure slow and steady fiber optic filament production.

- Long strokes. Travel length of the preform from insertion to heating the element is about six meters. It is best to do this with only a ball screw, which requires shafts of up to eight meters long.

- Diameter. The diameter of the screw is also a factor in the robustness, operation, stability and durability of the motion. Diameters of 50, 63 and 80 mm are best to avoid screw bend due to the long stroke.

Thomson ball screws are available in lengths of up to eight meters, diameters of 80 mm or more and pitch up to 25 x 50 mm, making it the ideal ball screw for applications such as fiber optic filament production, which require slow, steady movement

Driving Next-Generation Communications

Automated production of fiber optic cable is just one way that ball screws are enabling a new generation of communications technology. Thomson Industries, for example, has customers using ball screws on the doors of furnaces used to process sapphire for mobile phone screen protectors and feeding electrodes to winding machines for lithium batteries that will be used in electric cars.

Although the fundamentals are the same, ball screw technology continues to advance in flexibility and applicability. Companies such as Thomson are supporting even more advanced innovation in other industries by consistently pushing the envelope in heavy load handling, stroke lengths, compactness and onboard intelligence, which will provide the motion control needed to support the emergence of 5G and future generations as well.