Integrating lead screws with stepper motors is a simple and cost-effective method of getting precise linear motion. But achieving that precision requires anti-rotational guidance, which must either be added externally by the user or designed in by the manufacturer. Determining which option makes sense for you requires an analysis of your need for a guidance system and weighing the advantages and disadvantages of each approach.

The need for anti-rotational guidance

The main components of a traditional motorised lead screw (MLS) are a stepper motor, lead screw and a nut that connects to the load in various ways. When the motor turns the lead screw, the nut and connected load should travel forward or backward to achieve the positioning required for the application. But if that nut is unsecured, it will rotate with the screw and no motion will translate across the axis.

There are two primary approaches for stabilising the nut to prevent this problem. One is to build an external guidance system yourself; the other is to purchase a system into which the actuator manufacturer’s design already secures the nut.

Building your own external guidance system

If you already utilise a motorised linear actuator (MLA) and have the technical knowledge and resources, you can design and add an anti-rotational assembly yourself. If your application has stroke lengths longer than 64 mm, loads heavier than 890 N, and speeds faster than 500 mm/s, an external system may be your best choice. Building your own guidance system, however, can be a time-consuming and somewhat risky process.

Probably the most critical factor in selecting an external vs. internal guidance strategy is the amount of space available for external structures. Common approaches for an external approach include some combination of profile rails, linear rails or other anchored assemblies, which attach to the nut to guide its movements with precision. (Figure 1) Then, depending on your design, the bill of materials will include fasteners, couplings and other components. How you mount the system, attach the load and ensure alignment are also critical success factors.

Figure 1: Fluid pumps can use external guidance systems in which a motorised lead screw increases pump pressure, while minimising equipment footprint and more accurately dispersing fluid (Image courtesy of Thomson Industries, Inc.)

If you address the above issues correctly, building your own guidance system could give you a little more flexibility in mapping a system to your application and may result in a little less component cost — especially if time and long-term maintenance are not factored in. But for smaller applications, you are almost always better off if anti-rotational guidance is built in by the manufacturer as the total cost of installation, including design time and other items, is often lower.

The benefits of built-in anti-rotational guidance

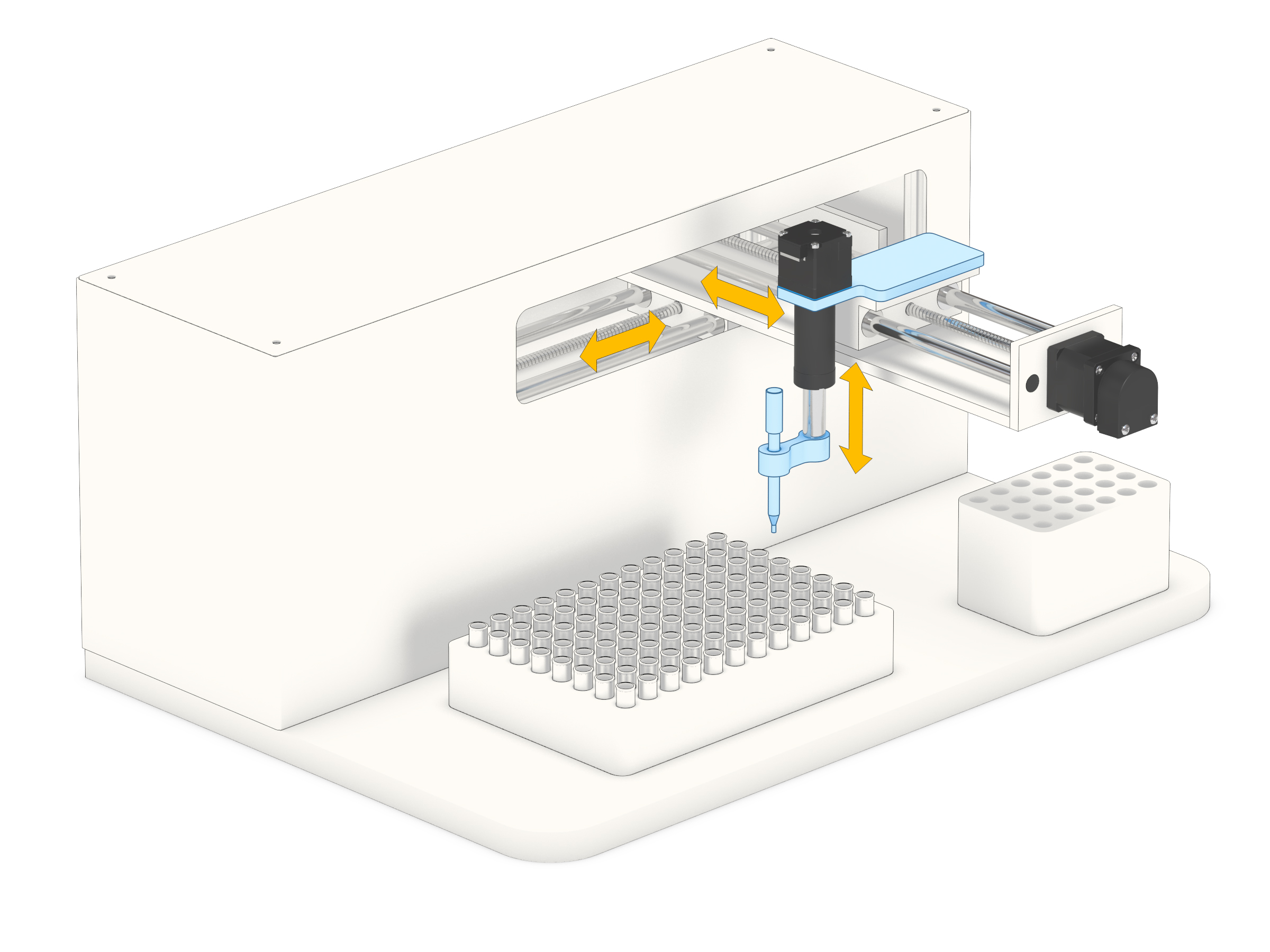

Figure 2 shows a pipetting system using an actuator with a built-in guidance system. Building all guidance technology into the actuator makes for a much simpler system. Most manufacturers accomplish the needed guidance by surrounding the lead screw shaft with a cover tube, which prevents the nut from rotating, while allowing it to move back and forth smoothly.

Figure 2: To ensure accurate pipetting, tiny, precise and repeatable vertical motion is required. Integrating motorised lead actuators simplifies your z-axis, while motorised lead screws provide precise and horizontal motion (Image courtesy of Thomson Industries, Inc.)

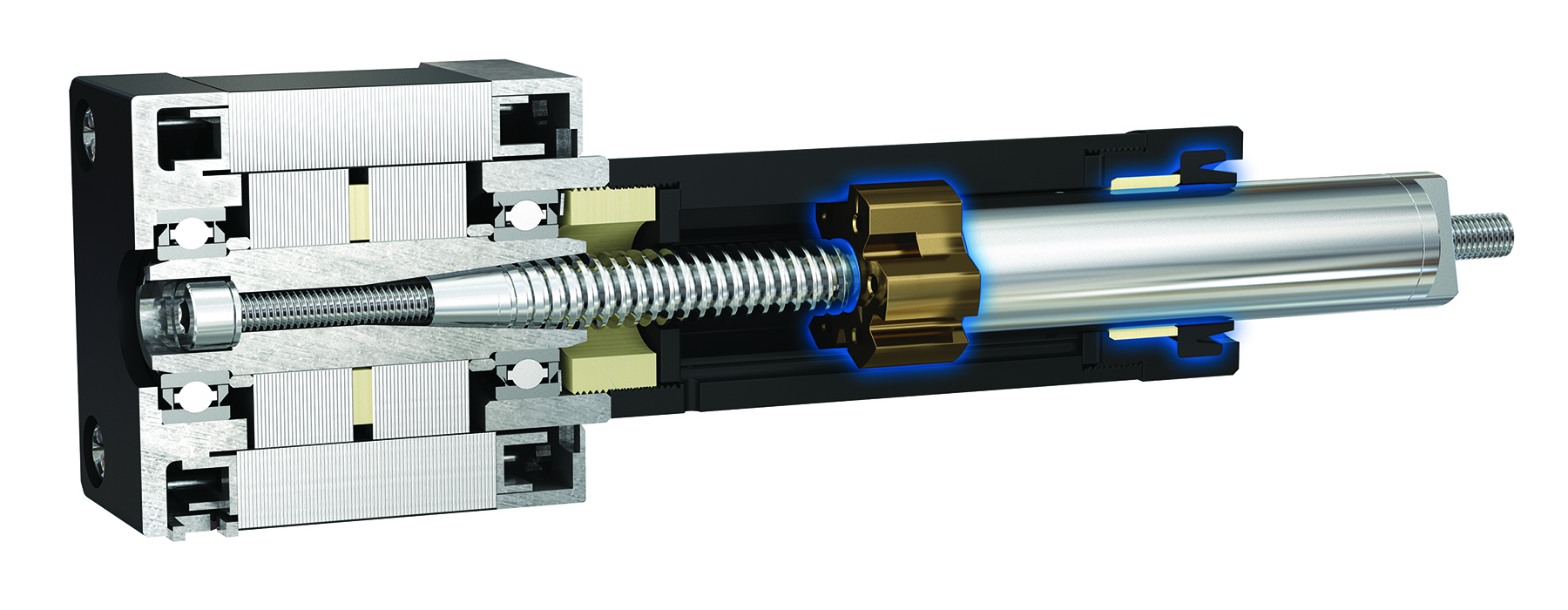

In the stepper motor, linear actuator from Thomson Industries, for example, the cover tube is made of aluminium and attaches to the motor, which is mounted firmly to a stable surface. (Figure 3) Splines moulded within the tube capture the nut to prevent it from rotating, thus enabling linear motion translation across the lead screw. The nut is attached to a stainless-steel extension tube, which connects to the load, moving it forward or backward, much like a traditional actuator.

Figure 3: The actuator configuration enables you to select a product based on linear travel per motor rotation and by including anti-rotation as standard, with no external requirements for guidance (Image courtesy of Thomson Industries, Inc.)

Purchasing stepper motor linear actuators with intrinsic anti-rotation eliminates the time, cost and maintenance involved in building it yourself. It also reduces the bill of materials that you have to deal with, and the longer-term cost of owning and operating your actuators. It is also aligned in the factory, which contributes to ongoing reliable performance.

Many high-precision applications with relatively short strokes can benefit from this approach. In addition to applications involving probing from vertical positions to dispense chemicals — like the illustrated pipetting applications — examples include precision proportional valve control, microscope slide stage adjustment and computer monitor tilting.

Selecting the right built-in technology Generally, stepper motor linear actuators are available for standard stepper motor sizes (NEMA 8, 11, 14, 17 and 23 motor frame sizes); single or double stacked; with a variety of motor winding options; and linear resolution options ranging from 0.002 – 0.191 µm of linear travel per step. Available offerings may, however, differ in their ability to handle radial and moment loads, capability to integrate other devices, visibility of rotating parts, mounting options, and customisation capability, so it is wise to consider your needs in these areas before purchasing one.

- Radial and moment load handling. Although most related applications involve axial loads, a properly fitted system should be able to achieve radial or moment loads of five to ten percent of the axial load. If your application requires radial and moment load handling, look for actuators with integrated bushings or other features that provide this ability for “side load.”

- Integrating external devices. There is certainly a trend toward integrating multiple devices to improve control and reduce maintenance costs. It may, for example, be desirable to attach linear encoders to the back of the stepper motor. To keep this option open, avoid assemblies in which the screw extends out the back of the motor.

- Mounting. If you are replacing existing motors, you can save yourself some trouble by purchasing a motor with NEMA-standard bolt-hole patterns. Hole positions can always be customised, but starting with the NEMA standard will save you trouble on initial purchase and into the future.

- Customisation – In addition to bolt-hole pattern customisation, customisation options include end machining, wiring, cabling and connectors.

If you have skilled resources in house, building your own anti-rotational guidance for your integrated motorised lead screw actuator might have some short-term cost advantages. However, purchasing an integrated stepper motor linear actuator will get you into production faster and provide more accurate and reliable motion, while reducing longer-term maintenance and total cost of ownership