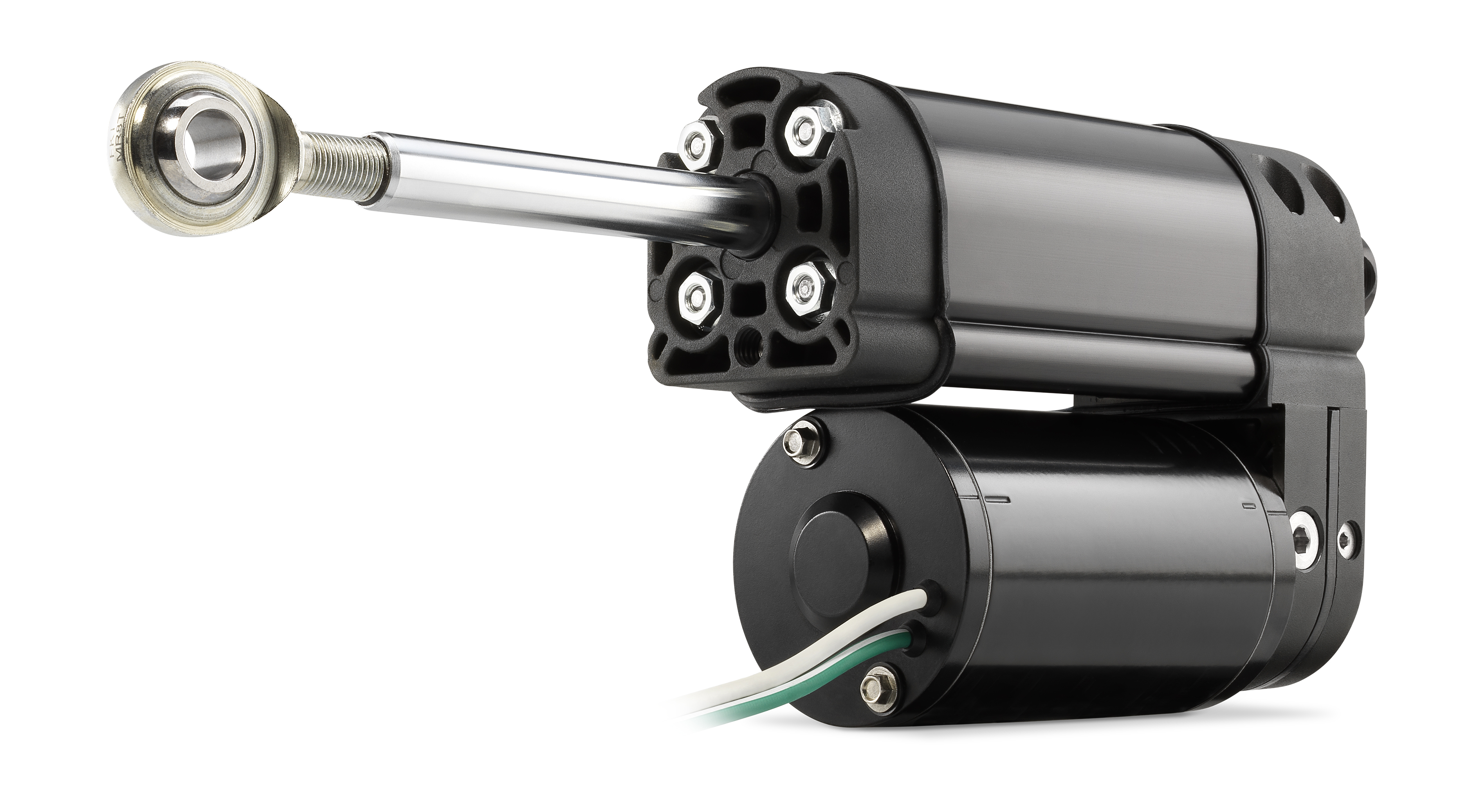

Thomson Industries, Inc., a leading manufacturer of linear motion solutions, has introduced an electro-hydraulic actuator that has the strength of hydraulic cylinders but without their complex external assemblies or extensive fluid handling requirements. Thomson Warner Linear H-Track actuators move loads of up to 4800 pounds from a compact mounting envelope. The actuators are ideal for space-constrained applications requiring high load handling and shock resistance, such as snowplow blade control, agricultural plows and sprayer booms, mower deck lifts, and UTV dump boxes.

“Specifying solutions for applications requiring high force in a compact space is now possible, while still realizing the benefits of an electrically driven actuator,” said Matt Palmer, Product Line Specialist – Linear Actuators for Thomson. “With our unique reservoir design and pump configuration, we have miniaturized a hydraulic system and embedded it into a package that is even smaller than a ball screw-style electromechanical system. The result is a compact, electro-hydraulic actuator rated for heavy loads and capable of withstanding large amounts of shock loading with fluid-powered actuation that cushions the actuator components.”

High force density and shock resistance

Hydraulic cylinder-based systems require a complex assembly of hoses, pumps, valves and reservoirs. This infrastructure can be costly to install, operate and maintain, and the fluid itself requires careful handling. Thomson Warner Linear H-Track actuators resolve this issue with a miniaturized hydraulic pump that is powered by a DC motor. The pump, cylinder and reservoir are a single unit that fits into a small housing about the size of a screw-type actuator. This hybrid actuator has a force rating of 4800 lbf (21 kN) and can achieve travel speeds of nearly 4 in. (100 mm) per second. Users can select between motors and pumps to optimize for higher load capacity or higher speed than can typically be attained with ball screw-based designs.

Using hydraulic power to create linear motion also has a cushioning effect that enables the system to absorb shock load that might otherwise bend the ball screw or the extension tube, especially if the shock load occurred while the actuator was extended.

High configuration flexibility

The ability to configure multiple pump and cylinder sizes enables Thomson to create H-Track iterations with various levels of speed and load capacity. Its exclusive pumping and reservoir architecture minimizes components and optimizes the volume/pressure differential. A patented split-tank shuttle valve with back pressure relief adds further efficiencies. Other H-Track features include:

- Bore and rod combinations that allow for multiple configurations.

- Stroke lengths up to 16 in. with solid rods allow for increased resistance to buckling.

- A pin-to-pin length shorter than traditional electromechanical actuators.

- Immunity to vibrational drifting; hydraulic self-locking.

- Protection from load runaway by installing meter-out circuits on one or both sides of the actuator. ? A cover-tube reservoir that cools the fluid.

- A flexible lid on a vented, isolated reservoir, which allows for actuator and pump operation in any orientation without entraining air or cavitation.

Numerous applications

The Thomson Warner Linear H-Track actuator is ideal for space-constrained applications that would usually use a screw-type actuator but would benefit from higher force handling, speeds or tolerance to shock loading. It is also ideal for applications that typically use hydraulic cylinders but in which the external pump and hose assemblies are consuming too much space or requiring too much maintenance. Following are some typical H-Track applications:

- Snowplowing — preventing bending of ball screw, extension tube or gearing if the plow collides with a hidden concrete obstacle while the actuator is fully extended.

- Agricultural plow depth control — controlling depth of blade penetration to optimize the placement of seeds from automatic seeders.

- Larger agricultural sprayer transport — protecting from overload on actuators used to fold larger sprayer booms for transport.

- Mower deck lifts — improving control of increasingly larger mower decks.

Electro-hydraulic actuators are also being used in a wide variety of other applications as well, including turf care, lawn and gardening, marine hatch lifts, industrial pallet lifts, UTV tailgate locks and dump boxes, and construction quick-attach bucket releases.

In addition to providing strength and resilience, H-Track electro-hydraulic actuators are designed for use in challenging environments. They are sealed to eliminate leakage of hydraulic fluids. They are also rated IP67 and IP69K for static loads, IP65 for dynamic loads and for 500-hour salt spray resistance. Units have a wide operating temperature range of -40? to 180?F (-40? to 82?C).

Thomson Warner Linear H-Track linear actuators are available immediately in stroke lengths of up to 16 in. For more information on these actuators, visit

https://www.thomsonlinear.com/en/products/linear-actuators/h-track.

About Thomson Industries, Inc.

With more than 70 years of achievement in motion control innovation and quality, Thomson is the industry’s premier producer of Linear Actuators, Linear Ball Bushing® Bearings and Profile Rail Bearings, 60 Case® Shafting, Ground and Rolled Ball Screws, Linear Systems, and related accessories. Thomson invented the Linear Ball Bushing Bearing in 1945 and has set the standard ever since with an unsurpassed set of linear motion control solutions serving global aerospace and defense, medical and health, factory automation, food processing, and mobile off-highway markets. Thomson, a brand of U.S.-based Altra Industrial Motion, has facilities in North America, Europe and Asia with more than 2000 distributor locations around the world.

For more information

Thomson Industries, Inc., 1500 Mittel Boulevard, Wood Dale, IL 60191-1073; 1-540-633-3549; 1-540-633-0294 (fax); Thomson@thomsonlinear.com; www.thomsonlinear.com.